Filtrace, regulace a úprava stlačeného vzduchu

Úprava stlačeného vzduchu je neopomenutelnou součástí kompresorové soustavy. Upravovat stlačený vzduch potřebujete z toho důvodu, že v sobě přirozeně má částečky prachu, oleje a v neposlední řadě kondenzát. Tato kombinace je velice škodlivá pro každé zařízení, které ke kompresoru připojíte. Koroze, ucpávání a přidírání pohyblivých součástí zkracuje životnost ventilů, pneumatického nářadí i součástí automatizovaných linek. Proto vám přinášíme komplexní program úpravy vzduchu, který obsahuje sušičky vzduchu, filtry, regulátory tlaku, separátory a cyklónové odlučovače. Díky našemu programu úpravy vzduchu násobně prodloužíte životnost celé vaší kompresorové soustavě a vyhnete se drahým servisům či odstávkám linek. Více o tom, jak filtrovat a upravovat vzduch v pokračování.

#ShowMore#

Základní principy úpravy vzduchu:

- sušení - sušičky vzduchu (kondenzační sušičky, adsorpční sušičky, membránové sušičky)

- filtrace - vzduchové filtry dle ISO 8573 (filtrace vzduchu, vysokotlaké filtry, procesní filtry, vakuové filtry)

- regulace - regulátory tlaku vzduchu na rozvodech před samotnou aplikací

- zbavení se kondenzátu a oleje (cyklónové odlučovače, separace voda – olej)

Podle čeho se řídit? - Třídy kvality stlačeného vzduchu dle ISO 8573-1

Jak vědět, jakou kvalitu má mít stlačený vzduch pro vaší aplikaci? Vodítkem je norma ISO 8573-1. Kvalita vyrobeného vzduchu je v normě popsána sedmi třídami, od 0 až do 6. Každá třída má předepsaný maximální obsah pevných částic, vody a oleje. Pro různé aplikace a průtoky jsou tedy požadovány různé třídy čistoty. Například pro dílenský vzduch je normou nařízena kvalita 4-4-5. Toto trojčíslo udává tři předepsané třídy kvality v pořadí - třída kvality pro pevné částice, třída kvality pro vodu, třída kvality pro olej. Nejvyšší nároky jsou samozřejmě ve farmacii, v chemickém průmyslu a potravinářství.

Detailně od třídách kvality mluvíme v našem článku z poradny: Jak filtrovat stlačený vzduch

Úprava vzduchu krok za krokem

Za kompresor je nejvhodnější použít sušičku vzduchu, která nám zajistí odstranění kondenzátu. Mezi sušičku vzduchu a kompresor se doporučuje použít předfiltraci. Jiné požadavky mají řemeslníci a jiné jsou v lékařském prostředí. Proto je potřeba zjistit čistotu vzduchu v mikronech. Tuto filtraci pak řadíme za sušičku. Nakonec můžeme stlačený vzduch regulovat na požadovaný tlak (atmosféry). Veškeré příslušenství, které nám slouží k úpravě vzduchu se časem opotřebí a je potřeba vyměňovat filtrační vložky nebo granulát. K měření opotřebení filtrací využíváme indikace zanesení a nebo diferenční manometry. Toto příslušenství naleznete pouze u lepších filtrů pro úpravu stlačeného vzduchu.

Další články o úpravě vzduchu z naší poradny:

Řazení produktů

Výpis produktů

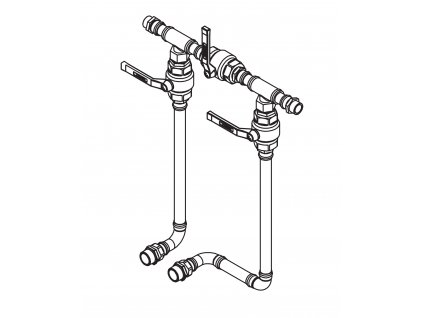

Bypass nebo-li obchozí potrubí pro sušičky stlačeného vzduchu Omega Air RDP-140/RDT-140 až RDP-235/RDT-235 pro snadnou údržbu a servis stroje.

Kondenzační sušič stlačeného vzduchu na rosný bod +5°C. Maximální vstupní tlak je 13 bar s průtokem až 235 m³/hod (3 916 l/min) a připojením pomocí vnějšího závitu G 1". Proces...

Kondenzační sušič stlačeného vzduchu na rosný bod +3°C. Maximální vstupní tlak je 14 bar s průtokem až 100 m³/hod (1 666 l/min) a připojením pomocí vnějšího závitu G1". Proces...

Předfiltr pro stlačený vzduch od značky Hankison řady NGF typu HF dle ISO. Velikost filtru F08 s připojením pomocí vnitřních závitů 1". Filtr je vybaven indikátorem zanesení a...

Základní ISO filtr pro stlačený vzduch od značky Hankison řady NGF typu SF. Velikost filtru F08 s připojením pomocí vnitřních závitů 1". Filtr je vybaven indikátorem zanesení a...

Základní filtry AFP dle ISO 8573.1 s filtrační schopností 3 um a efektivitou 99,9%. Filtry FPRO slouží k odstranění největších mechanických nečistot ze stlačeného vzduchu. Tělo...

Základní filtr AAFP v provedení 1" k odstranění základních mechanických nečistot do 3 um ze stlačeného vzduchu dle ISO 8573-1 třída 6. Tělo se snadno odmontovatelnou nádobkou a...

Základní filtr AAFP v provedení 1" k odstranění základních mechanických nečistot do 3 um ze stlačeného vzduchu dle ISO 8573-1 třída 6. Tělo se snadno odmontovatelnou nádobkou a...

Předfiltr AAFM v provedení 1" k odstranění jemných nečistot do 0,1 um ze stlačeného vzduchu dle ISO 8573-1 třída 2. Tělo se snadno odmontovatelnou nádobkou a s konstrukcí pro...

Adsorpční filtr s aktivním uhlím AAFA2 v provedení 1" pro pohlcování zbytkového obsahu oleje, olejových výparů a aerosolů s obsahem < 0,005 mg/m3 ze stlačeného...

Filtr s aktivním uhlím AAFA v provedení 1" pro pohlcování zbytkového obsahu oleje, olejových výparů a aerosolů s obsahem < 0,005 mg/m3 ze stlačeného vzduchu dle ISO...

Filtr s aktivním uhlím AAFA v provedení 1" pro pohlcování zbytkového obsahu oleje, olejových výparů a aerosolů s obsahem < 0,005 mg/m3 ze stlačeného vzduchu dle ISO...

Filtry slouží k odstranění největších mechanických nečistot ze stlačeného vzduchu do 1 um dle ISO 8573-1 třída 3. Tělo se snadno odmontovatelnou nádobkou a s konstrukcí pro...

Mikrofiltr AAFS v provedení 1" k odstranění mikro nečistot do 0,01 um ze stlačeného vzduchu dle ISO 8573-1 třída 1. Tělo se snadno odmontovatelnou nádobkou a s konstrukcí pro...

Prachový filtr AAFR v provedení 1" k odstranění prachových nečistot do 1 um ze stlačeného vzduchu dle ISO 8573-1 třída 3. Tělo se snadno odmontovatelnou nádobkou a s konstrukcí...

Filtry AFM slouží k odstranění největších mechanických nečistot ze stlačeného vzduchu do 0,1 um dle ISO 8573-1 třída 2. Tělo se snadno odmontovatelnou nádobkou a s konstrukcí...

Kondenzační sušič stlačeného vzduchu na rosný bod +3°C. Maximální vstupní tlak je 14 bar s průtokem až 144 m³/hod (2 333 l/min) a připojením pomocí vnějšího závitu G1". Proces...

Kondenzační sušič stlačeného vzduchu na rosný bod +3°C. Maximální vstupní tlak je 14 bar s průtokem až 50 m³/hod (833 l/min) a připojením pomocí vnějšího závitu G1". Proces...

Adsorpční sušička BDRY-250 navržena pro trvalou separaci vodních par ze stlačeného vzduchu o průtoku až 3 400 l/min o maximálním tlaku 16 bar a redukci tlakového rosného bodu až...

Adsorpční sušička BDRY-150 navržena pro trvalou separaci vodních par ze stlačeného vzduchu o průtoku až 1 958 l/min o maximálním tlaku 16 bar a redukci tlakového rosného bodu až...

Adsorpční sušička BDRY-110 navržena pro trvalou separaci vodních par ze stlačeného vzduchu o průtoku až 1 433 l/min o maximálním tlaku 16 bar a redukci tlakového rosného bodu až...

Adsorpční sušička BDRY-200 navržena pro trvalou separaci vodních par ze stlačeného vzduchu o průtoku až 2 617 l/min o maximálním tlaku 16 bar a redukci tlakového rosného bodu až...

Cyklonový odlučovač AAFC v provedení 1" o průtoku 3 300 l/min k částečnému odstranění kondenzátu ze stlačeného vzduchu. Zde se proudění změní na rotační a v důsledku rotace a...

Kondenzační sušič stlačeného vzduchu na rosný bod +5°C. Maximální vstupní tlak je 13 bar s průtokem až 100 m³/hod (1 666 l/min) a připojením pomocí vnějšího závitu G 1". Proces...

Mikrofiltr CHP4S s přípojným závitem G1" určený k efektivnímu odstranění pevných nečistot, oleje, vody a dalších příměsí ze stlačeného vzduchu do 0,01 um. Maximální pracovní...

Filtr s aktivním uhlím CHP4A s přípojným závitem G1" určený k efektivnímu odstranění pevných nečistot, oleje, vody a dalších příměsí ze stlačeného vzduchu do 0,005 um. Maximální...

Prachový filtr CHP4R s přípojným závitem G1" určený k efektivnímu odstranění prachových nečistot, oleje, vody a dalších příměsí ze stlačeného vzduchu do 1 um. Maximální pracovní...

Předfiltr CHP4M s přípojným závitem G1" určený k efektivnímu odstranění pevných nečistot, oleje, vody a dalších příměsí ze stlačeného vzduchu do 0,1 um. Maximální pracovní tlak...

Sintrovaný hrubý filtr CHP4B s přípojným závitem G1" určený k efektivnímu odstranění pevných nečistot, oleje, vody a dalších příměsí ze stlačeného vzduchu do 15 um. Maximální...

Základní filtr CHP4P s přípojným závitem G1" určený k efektivnímu odstranění pevných nečistot, oleje, vody a dalších příměsí ze stlačeného vzduchu do 3 um. Maximální pracovní...

Předfiltr AAFM v provedení 1" k odstranění jemných nečistot do 0,1 um ze stlačeného vzduchu dle ISO 8573-1 třída 2. Tělo se snadno odmontovatelnou nádobkou a s konstrukcí pro...

Prachový filtr AAFR v provedení 1" k odstranění prachových nečistot do 1 um ze stlačeného vzduchu dle ISO 8573-1 třída 3. Tělo se snadno odmontovatelnou nádobkou a s konstrukcí...

Mimořádně tichý a bezprašný chod kondenzační sušičky stlačeného vzduchu do průtoku 260 m³/hod z kompresoru na 3°C rosného bodu umožňuje využití v laboratořích s vysokými nároky...

Malá kondenzační sušička pro odstranění vlhkosti ze stlačeného vzduchu od kompresoru až do rosného bodu +5°C. Maximální průtok vzduchu 3600 l/min s automatickým odpouštěním...

Kondenzační sušička řady MDX400 o maximálním průtoku 3 000 l/min a vstupním tlakem až 14 bar slouží k odstranění kondenzátu a vlhkosti ze stlačeného vzduchu vyrobeného...

Malá kondenzační sušička pro odstranění vlhkosti ze stlačeného vzduchu od kompresoru až do rosného bodu +5°C. Maximální průtok vzduchu 3000 l/min s automatickým odpouštěním...

Nerezový prachový filtr IHP1R s přípojným závitem G1" určený k efektivnímu odstranění prachových nečistot, oleje, vody a dalších příměsí ze stlačeného vzduchu do 1 um. Maximální...

Hrubý filtr AAFB v provedení 1" k odstranění největších mechanických nečistot do 15 um ze stlačeného vzduchu dle ISO 8573-1 třída 7. Tělo se snadno odmontovatelnou nádobkou a s...

Hrubý filtr AAFB v provedení 1" k odstranění největších mechanických nečistot do 15 um ze stlačeného vzduchu dle ISO 8573-1 třída 7. Tělo se snadno odmontovatelnou nádobkou a s...

Kondenzační sušička řady MDX2400 o maximálním průtoku 2 350 l/min a vstupním tlakem až 14 bar slouží k odstranění kondenzátu a vlhkosti ze stlačeného vzduchu vyrobeného...

-hankison-susicka-vzduch-kompresor-tllak-kondenzace-rosny-bod.jpg)