Aluminium Profile BH 45-10, 45x60, Heavy Duty

Code: 084.105.007

Related products

Product detailed description

Aluminium profile with a rectangular cross-section designed for creating standard structures with higher loads in the direction of the longer side.

Heavy-duty option weighing 2.80 kg/m.

Versatile connection options thanks to 4 grooves on all sides of the profile.

Made from EN AW 6060 T5 aluminium alloy, anodised layer of more than 12 microns, tolerance according to EN 12020-2.

Possible delivery in large packages - small bundle of 2 bars, large bundle of 60 bars.

Compatibility

This product can replace the following products on the market:

| Code | Ord. C. | Note |

|---|---|---|

| REX | 3 842 557 200 | weight 3.00 kg/m; bundle of 20 bars |

| REX | 3 842 990 570 | weight 3.00 kg/m |

| REX | 3 842 990 571 | weight 3.00 kg/m; machining - M12 thread on one side |

| REX | 3 842 990 572 | weight 3.00 kg/m; machining - M12 thread on both sides |

| REX | 3 842 990 573 | weight 3.00 kg/m; machining - M16 thread on one side |

| REX | 3 842 990 574 | weight 3.00 kg/m; machining - milling L=30 mm, 20 mm from the edge in the groove on the 45 mm side on one side |

| REX | 3 842 990 575 | weight 3.00 kg/m; machining - M12 thread on one side, M16 thread on the other side |

| REX | 3 842 990 670 | weight 3.00 kg/m; machining - perpendicular hole D=17 on both sides |

| REX | 3 842 990 672 | weight 3.00 kg/m; machining - lateral hole D=17 on both sides |

| REX | 3 842 990 674 | weight 3.00 kg/m; machining - lateral hole D=17 on one side, perpendicular hole D=17 on the other side |

| REX | 3 842 990 688 | weight 3.00 kg/m; machining - lateral hole D=17 on one side |

| REX | 3 842 990 690 | weight 3.00 kg/m; machining - perpendicular hole D=17 on one side |

| REX | 3 842 992 375 | weight 3.00 kg/m; machining - perpendicular hole D=9.8 on one side |

| REX | 3 842 992 376 | weight 3.00 kg/m; machining - lateral hole D=9.8 on one side |

| REX | 3 842 993 085 | weight 3.00 kg/m; machining - countersinking D=17 in both grooves on the 60 mm side on both sides |

| REX | 3 842 993 743 | weight 3.00 kg/m |

| REX | 3842557200 | weight 3.00 kg/m; bundle of 20 bars |

| REX | 3842990570 | weight 3.00 kg/m |

| REX | 3842990571 | weight 3.00 kg/m; machining - M12 thread on one side |

| REX | 3842990572 | weight 3.00 kg/m; machining - M12 thread on both sides |

| REX | 3842990573 | weight 3.00 kg/m; machining - M16 thread on one side |

| REX | 3842990574 | weight 3.00 kg/m; machining - milling L=30 mm, 20 mm from the edge in the groove on the 45 mm side on one side |

| REX | 3842990575 | weight 3.00 kg/m; machining - M12 thread on one side, M16 thread on the other side |

| REX | 3842990670 | weight 3.00 kg/m; machining - perpendicular hole D=17 on both sides |

| REX | 3842990672 | weight 3.00 kg/m; machining - lateral hole D=17 on both sides |

| REX | 3842990674 | weight 3.00 kg/m; machining - lateral hole D=17 on one side, perpendicular hole D=17 on the other side |

| REX | 3842990688 | weight 3.00 kg/m; machining - lateral hole D=17 on one side |

| REX | 3842990690 | weight 3.00 kg/m; machining - perpendicular hole D=17 on one side |

| REX | 3842992375 | weight 3.00 kg/m; machining - perpendicular hole D=9.8 on one side |

| REX | 3842992376 | weight 3.00 kg/m; machining - lateral hole D=9.8 on one side |

| REX | 3842993085 | weight 3.00 kg/m; machining - countersinking D=17 in both grooves on the 60 mm side on both sides |

| REX | 3842993743 | weight 3.00 kg/m |

| FMS | 05.01011.00 | weight 3.30 kg/m |

| FMS | 05.01043.00 | weight 2.19 kg/m |

| FMS | 05.01499.00 | weight 2.85 kg/m |

Warning: the alternative product we offer may have technical deviations from the original product. Please contact us to explain the differences.

Joining profiles

The choice of fixings between different profiles is very important in any assembly structure. The customer can choose from various solutions depending on the required implementation time or the nature of the load or load-bearing capacity.

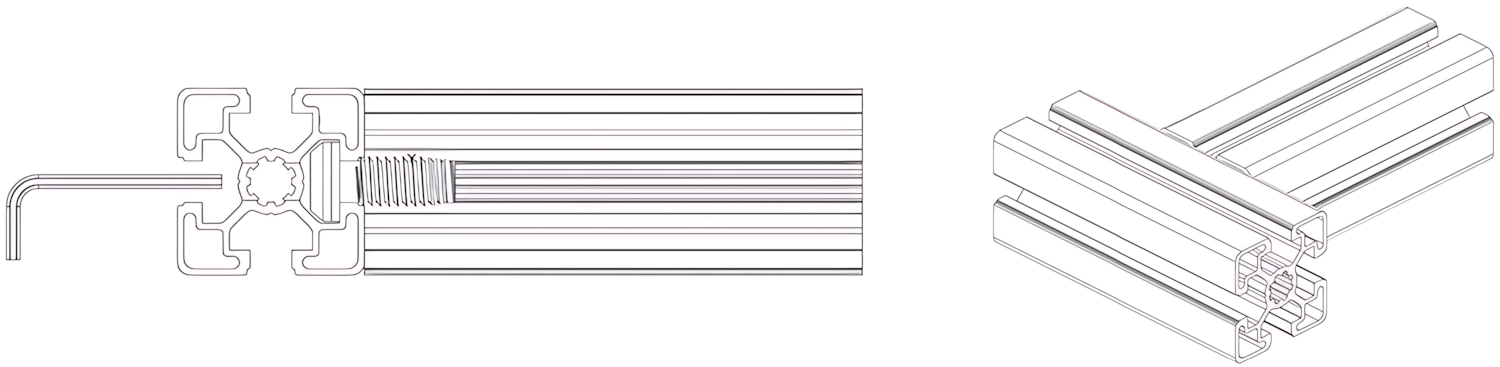

1. Joining with screws in the groove

This is the simplest and fastest way to assemble. This connection system guarantees good perpendicularity between two surfaces (depending on the profile section) and good resistance of the mutual connection in the transverse direction to the groove.

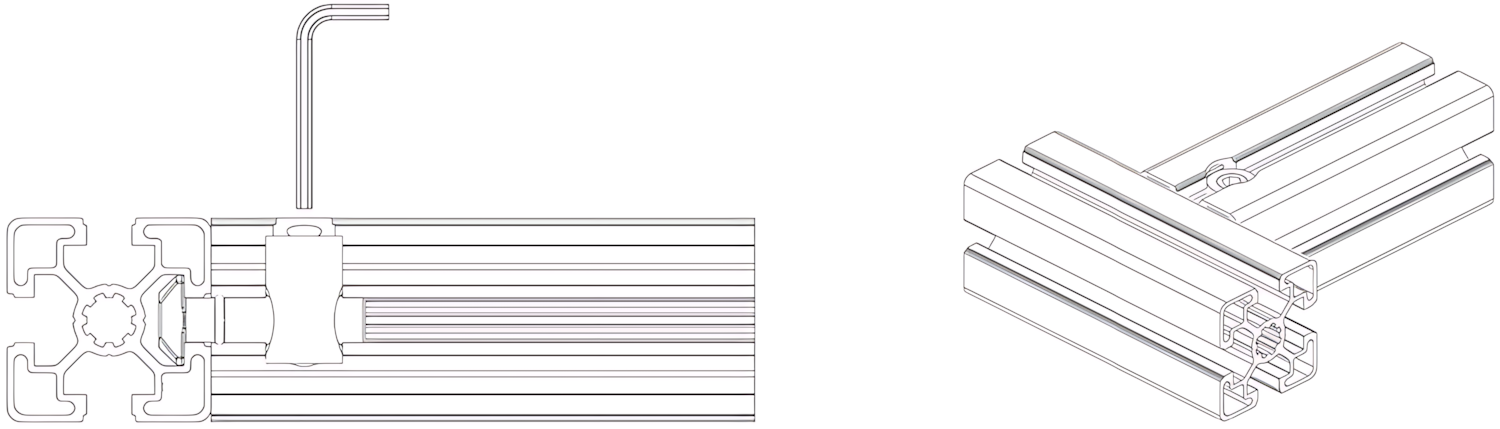

2. Joining with a connecting latch

This assembly is very simple and safe and guarantees a firm connection even if the screws are loosened.

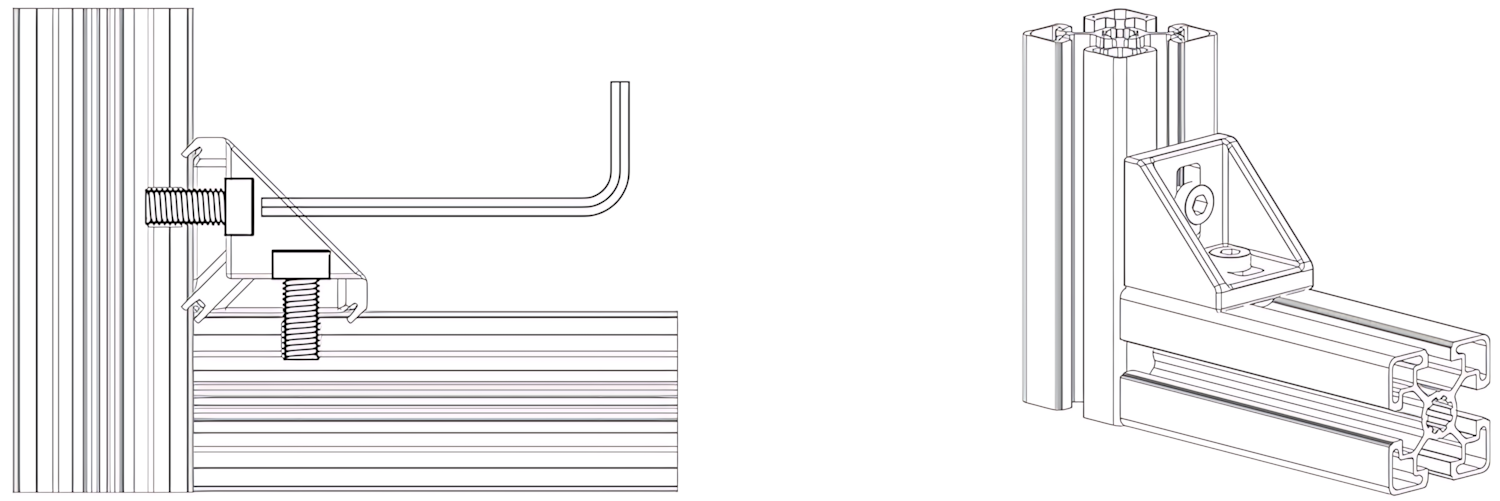

3. Joining with joints or angles

This method of joining is usually used where the greatest possibilities of adjustment and easy installation are required. Technical specifications for all products can be found in the product details of the relevant accessory.

Profile threads

It is recommended to respect the depth indicated in the table when creating a thread:

| Profile | Screw diameter | Recommended depth (mm) |

| slot 6 | M6 | 15 |

| slot 8 | M8 | 25 |

| slot 10 | M12 | 30 |

The maximum tightening torques recommended for screws used in the ALUSIC system are:

| Profile | Screw diameter | Max. recommended tightening torque (Nm) |

| slot 6 | M6 | 10 |

| slot 8 | M8 | 20 |

| slot 10 | M12 | 35 |

Compatible accessories for all types of panel connections can be found in the related products tab

Additional parameters

| Category: | Aluminum profiles BH 45x60 |

|---|---|

| Warranty: | 2 years |

| Hmotnost (kg/m): | 2.8 |

| In stock: | External warehouse |

| Řez profilu: | 45×60 |

| Série: | BH 45-10 |

| Material: | anodized aluminum |

| Color: | natural |

| Profile length (mm): | 6 040 |

| Moment of inertia lx (cm⁴): | 35,00 |

| Moment of inertia ly (cm⁴): | 20,90 |

| Sectional moment wx (cm³): | 11,70 |

| Section moment wy (cm³): | 9,30 |

| Cutting area (mm²): | 1 038 |

| Minimum length (mm): | 30 |

| Maximum length (mm): | 6 000 |

| Rust: | CUT-A |

| Cut link: | /profile-a-corrosion/ |

Hliníkové profily Alusic

Be the first who will post an article to this item!

Be the first who will post an article to this item!