SCR-APM Mini Screw Compressors

|

|

SCR APM screw compressors with power input up to 5.5 kW and frequency converter |

||||||||||||

| Ordering number |

Exit " |

Displacement m³/h |

Displacement l/min |

Dryer air |

Air tank l |

Pressure bar |

Power consumption kW |

Dimensions mm |

Weight kg |

Noise db(A) |

||

| d | with | in | ||||||||||

| SCR-3/10APM | 1/2" | 7,8 - 19,2 | 130 - 320 | - | - | 10 | 3 | 650 | 600 | 860 | 180 | 65 |

| SCR-4/10APM | 1/2" | 12,0 - 30,6 | 200 - 510 | - | - | 10 | 4,7 | 650 | 600 | 860 | 180 | 65 |

| SCR-5.5/10APM | 1/2" | 16,9 - 41,4 | 280 - 690 | - | - | 10 | 5,5 | 650 | 600 | 860 | 180 | 65 |

| SCR-3/10APM-200D | 1/2" | 7,8 - 19,2 | 130 - 320 | +5 °C | 200 liters | 10 | 3 | 1 277 | 655 | 1 364 | 278 | 65 |

| SCR-4/10APM-200D | 1/2" | 12,0 - 30,6 | 200 - 510 | +5 °C | 200 liters | 10 | 4,7 | 1 277 | 655 | 1 364 | 280 | 65 |

| SCR-5,5/10APM-200D | 1/2" | 16,9 - 41,4 | 280 - 690 | +5 °C | 200 liters | 10 | 5,5 | 1 277 | 655 | 1 364 | 280 | 65 |

| SCO-5L | mineral oil, 5 l canister | |||||||||||

| SCO-20L | mineral oil, 20 l canister | |||||||||||

| * volumetric flow rate is measured according to ISO 1217 standard | ||||||||||||

#ShowMore#

Screw or piston compressor?

In crafts, workshops and smaller production plants, piston compressors are generally used as a traditional source of compressed air, mainly due to low acquisition costs. In recent years, however, there has been considerable development of modern screw compressor technologies, even in the lower air consumption ranges that were previously the exclusive domain of piston compressors. With our new range of SCR-APM Mini screw compressors, you can now afford machines with modern technology at attractive prices and with many user benefits.

|

|

|

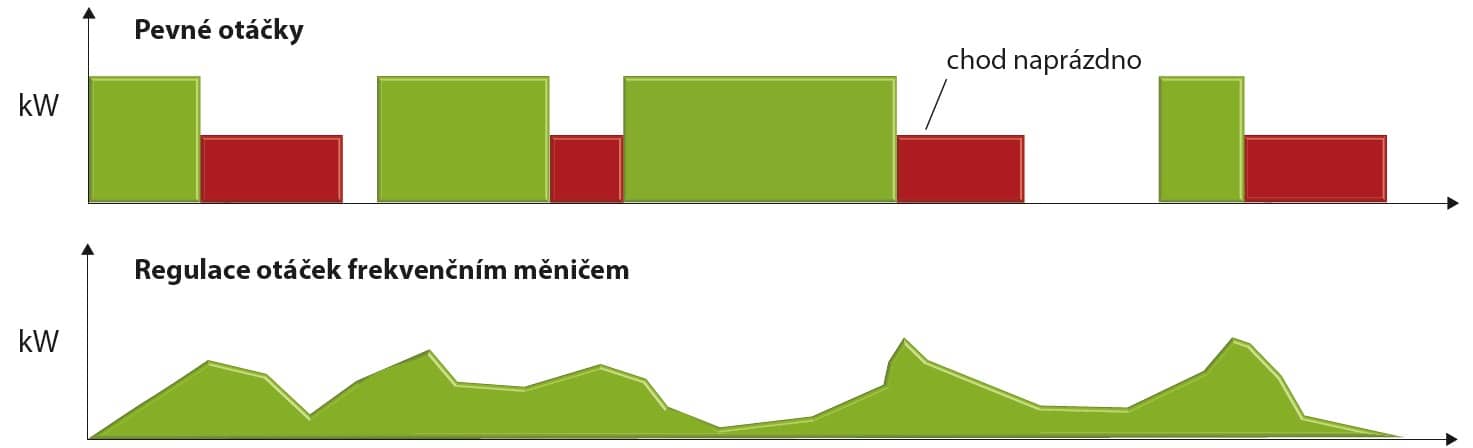

Modern, economical solutionsThe new generation of SCR-APM Mini compressors with modern technologies offers significantly lower energy consumption costs compared to piston compressors or older screw compressors with fixed speed operation and V-belt transmission. Given the high cost of energy, the investment in a new compressor pays for itself quickly. |

|

|

|

|

|

|

No idling |

No unnecessary pressure set the exact pressure you actually need on the IT7000 control unit |

Efficient IE4 motors with permanent magnets and lower losses |

No transmission losses thanks to the direct connection of the motor to the block compared to V-belts |

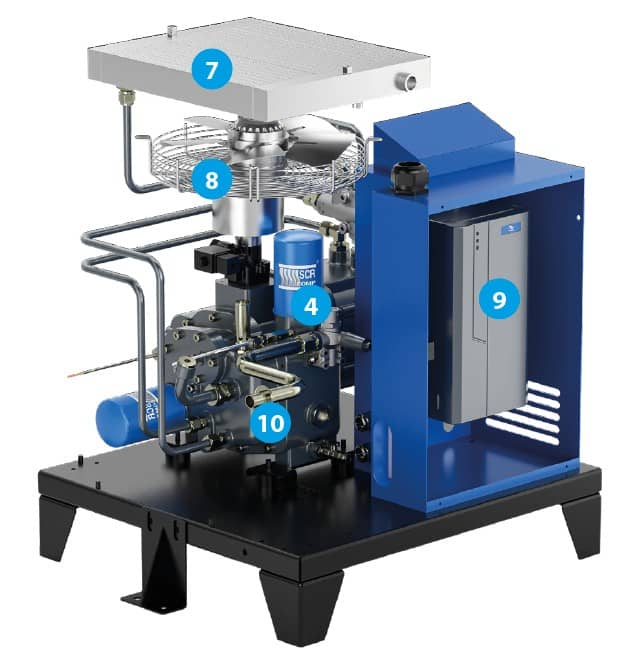

Design arrangement

The structural layout of the individual parts of SCR-APM Mini compressors is designed to make the entire machine as compact as possible and take up as little space as possible in operation, while taking into account good service access to all important components.

|

|

|

3in1 assemblies

|

We offer SCR-APM Mini series screw compressors not only in a separate design, but also in practical assemblies containing a compressor, a condensation dryer and a pressure vessel with a volume of 200 litres. This 3in1 concept, which ensures both the production and treatment of compressed air, makes installation as easy as possible, saves space and provides very high-quality air for powered devices and technologies.

|

|

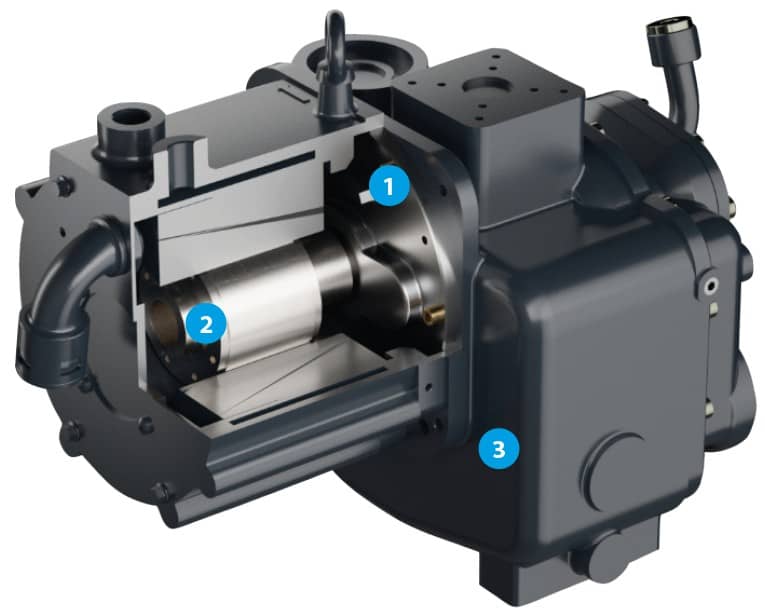

Screw block and drive system

The drive system is the basis of every screw compressor. In the SCR-APM Mini series compressors, the three main components, the screw block, the electric motor and the oil tank, are integrated into one very compact unit, which allows absolute minimisation of the machine's overall dimensions.

|

Screw block with low speeds Direct drive - without losses and maintenance-free Permanent magnet motors

|

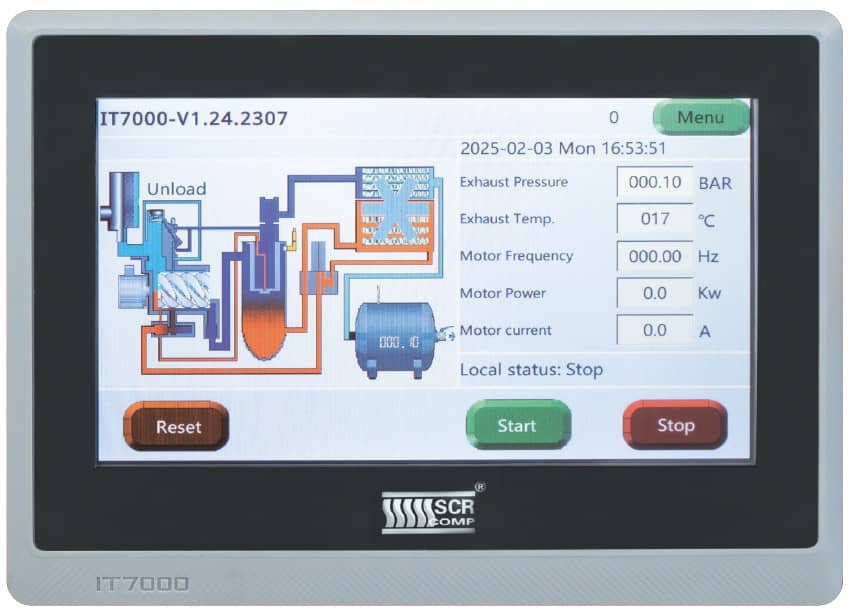

Electronic control unit

Although the SCR-APM Mini screw compressors are the smallest product line in the SCR production program, their operation is ensured by an above-standard modern IT7000 control unit with simple operation via a colour 7" touch screen display. The IT7000 unit has many useful functions for monitoring the status of the compressor, operating and service settings and necessary alarms.

|

IT7000 unit options

|

Variable Speed Drive Control

Traditional fixed-speed compressors are controlled in duty cycles, where the compressor operates alternately under load, idling, or stopped. Immediately after starting, air compression begins and the main motor is under load. When the required pressure is reached, it switches to idle mode, where the compressor does not produce air, but the motor continues to rotate the screw block in idle and requires energy. Idling facilitates further start-up of the machine, but for several tens of seconds there is unnecessary energy consumption, which usually reaches tens of percent of the total energy consumed. The lower the air consumption, the greater the proportion of idling and the greater the potential for significant savings in the cost of manufactured air and compressor operating costs.

Frequency converters with vector controlSCR-APM Mini compressors are equipped with state-of-the-art INOVANCE frequency converters that maintain the required output pressure and adapt the speed of the drive train to the immediate needs of the compressed air supply. Thanks to this modern compressor control system, it is significantly The vector control inverters used were developed specifically for screw compressor applications and provide very high torque at frequencies as low as 0.1 Hz. Conventional frequency inverters either cannot operate at frequencies below 5 Hz or are extremely inefficient in this range. The new generation of INOVANCE vector inverters thus ensures very high energy efficiency across the entire speed range. |

|

Operating Status Indication

|

The SCR-APM Mini series of screw compressors are equipped with perfect operating status signalling via effective front panel illumination. This practical solution allows you to see at a glance whether the compressor is under load and producing compressed air, or whether it is stopped or unloaded and not producing air.

|

Air dryerWhen air is compressed, water vapour contained in the air drawn from the atmosphere into the compressor condenses, creating a liquid emulsion called condensate. Condensate causes corrosion of pipes, parts of pneumatic tools, valves and pistons on production lines and machines, and can also damage finished products. The 3in1 sets of SCR-APM Mini screw compressors are equipped with RDL condensation dryers with modern ecological refrigerant R513a to eliminate moisture, ensuring a pressure dew point of +5 °C is achieved.

|

RDL dryer equipment

|

Quick and easy installation

If you need to address both compressed air production and treatment, then the ideal solution is the SCR-APM Mini compressor sets, which include a compressor, air receiver and dryer in one machine. 3-in-1 sets are not only a compact solution that takes up little space, but their installation takes a fraction of the time and money compared to assembling all the equipment separately.

Quality original parts & available service

|

To ensure the compressor consistently delivers peak performance and to minimise the risk of failure throughout its lifespan, it is essential to perform compressor maintenance at the specified intervals and exclusively with genuine spare parts and lubricants. All necessary spare parts are available for every SCR-APM Mini compressor and can be easily selected according to the supplied documentation or by their designation directly on the part located in the machine. Maintenance and servicing of SCR-APM Mini compressors are provided by an extensive network of service partners, ensuring that all necessary services are readily and quickly available without unnecessary technician travel costs. |

|

|

|

Extended 5-year warrantyWe are confident in the quality of the technical design of the SCR-APM Mini series compressors, the components used, and our production quality system. Therefore, we offer all customers the option to extend the standard warranty period to 5 years for an additional fee |

To ensure the compressor consistently delivers peak performance and to minimise the risk of failure throughout its lifespan, it is essential to perform compressor maintenance at the specified intervals and exclusively with genuine spare parts and lubricants.

All necessary spare parts are available for every SCR-APM Mini compressor and can be easily selected according to the supplied documentation or by their designation directly on the part located in the machine.

Maintenance and servicing of SCR-APM Mini compressors are provided by an extensive network of service partners, ensuring that all necessary services are readily and quickly available without unnecessary technician travel costs.

Bestsellers

Product sorting

List of products

The highly efficient screw compressor of the new generation SCR-APM Mini with stepless speed control using a frequency inverter significantly reduces idle running and brings...

The highly efficient screw compressor of the new generation SCR-APM Mini with stepless speed control using a frequency inverter significantly reduces idle running and brings...

The highly efficient screw compressor of the new generation SCR-APM Mini with stepless speed control using a frequency inverter significantly reduces idle running and brings...

The highly efficient screw compressor of the new generation SCR-APM Mini with stepless speed control using a frequency inverter significantly reduces idle running and brings...

The highly efficient screw compressor of the new generation SCR-APM Mini with stepless speed control using a frequency inverter significantly reduces idle running and brings...

The highly efficient screw compressor of the new generation SCR-APM Mini with stepless speed control using a frequency inverter significantly reduces idle running and brings...

Lossless float condensate drain

Lossless float condensate drain