Šroubové kompresory pro nepřetržitý provoz

Jedna z nejširších nabídek šroubových kompresorů na trhu sestavená z výrobků značky MARK a SCR a ATMOS. Kvalitní kompresory v mnoha stavebních řadách s příkonem od 2,2 do 160 kW. Verze s chodem on-off nebo s plynulou regulací otáček. Stavební sestavy kompresor-vzdušník-sušička dle přání zákazníka. Pohon pomocí klínových řemenů nebo moderní převodovky. Olejové i bezolejové provedení. Celá řada variant – integrované sušičky, monitoring, rekuperace, ventilátory, nadřazené řídicí systémy.

|

Záruka 5 let v ceně kompresoruNa všechny šroubové kompresory zakoupené v našem e-shopu nyní automaticky poskytujeme prodlouženou záruku 5 let, a to zcela zdarma – v ceně stroje. Tato nadstandardní záruka je důkazem kvality a spolehlivosti našich kompresorů. Díky pravidelnému servisu a používání originálních náhradních dílů máte jistotu, že váš kompresor bude pracovat dlouhodobě, efektivně a bezstarostně. |

#ShowMore#

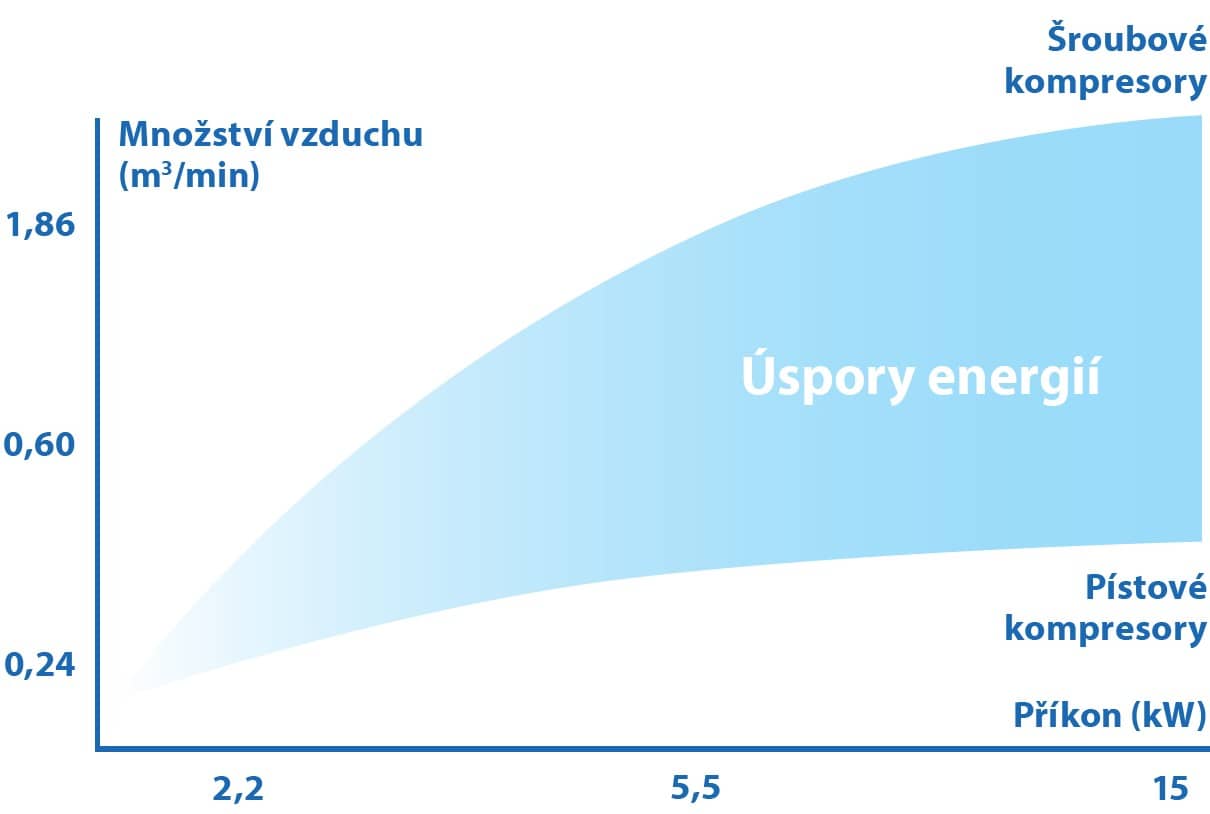

Šroubové kompresory - investice do energetických úsporVýroba stlačeného vzduchu pomocí moderních šroubových kompresorů je minimálně o 30% energeticky účinnější než s tradičními pístovými kompresory. Pokud chcete snížit provozní náklady na výrobu stlačeného vzduchu, je přechod na technologii šroubových kompresorů nejvhodnějším krokem, který můžete učinit. |

|

|

|

Hlavní výhody šroubových kompresorů

|

|

|

|

| Nepřetržitá dodávka vzduchu Šroubové kompresory mohou díky rotačnímu principu a výrazně lepšímu chlazení dodávat stlačený vzduch nepřetržitě a tím výrazně vylepší produktivitu práce. Nejste limitováni časem, kdy musí pístový kompresor odpočívat a můžete použít kompresor s výrazně menším příkonem. |

Vysoká úroveň kvality vzduchu Díky praktickým sestavám kompresorů vybavených kondenzační sušičkou získáte perfektní stlačený vzduch zbavený vlhkosti. Šroubové kompresory mají navíc integrovaný separační systém oleje a poskytují vzduch s minimálním obsahem oleje do 5 ppm, což je typicky 6× méně oleje než u pístových kompresorů. |

Redukovaná spotřeba energie Stlačování vzduchu pomocí šroubového bloku je výrazně energeticky účinnější než pomocí pístové kompresorové jednotky. V případě častého používání kompresoru ušetříte značné množství elektrické energie a snížíte finanční náklady spojené s výrobou vzduchu s rychlou návratností stroje. |

Nízký hluk na pracovišti Hlučnost šroubových kompresorů je přibližně o 20 dB(A) nižší než u tradičních pístových kompresorů bez speciálního odhlučnění. Šroubové kompresory poskytují maximální uživatelský komfort a lze je používat přímo na pracovišti, aniž by výrazněji ovlivnily hygienu práce. |

Moderní technologie pro ještě vyšší úspory

Výroba stlačeného vzduchu je energeticky velmi náročná. I provoz nejmenších šroubových kompresorů může pro uživatele znamenat roční náklady na elektrickou energii ve výši několika set tisíc Kč. V našem programu proto naleznete kromě tradičních šroubových kompresorů i stroje s nejmodernějšími technologiemi, které Vám poskytnou ohromné možnosti při dosažení tolik potřebných energetických a finančních úspor.

|

|

|

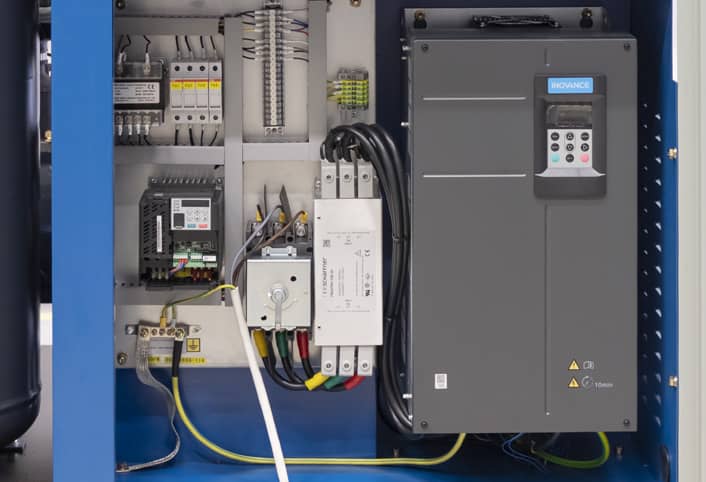

| 35 % - Frekvenční měnič Chod s regulací otáček zamezuje zbytečné spotřebě energie na chod bez zátěže a snižuje náklady i díky užšímu tlakovému pásmu pro řízení stroje. |

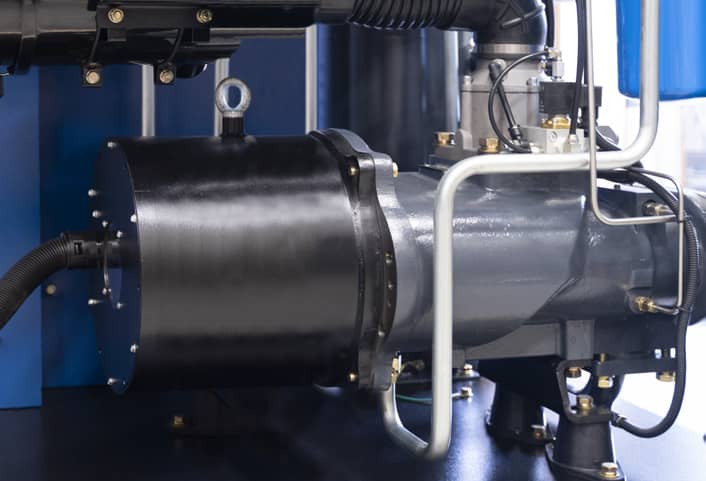

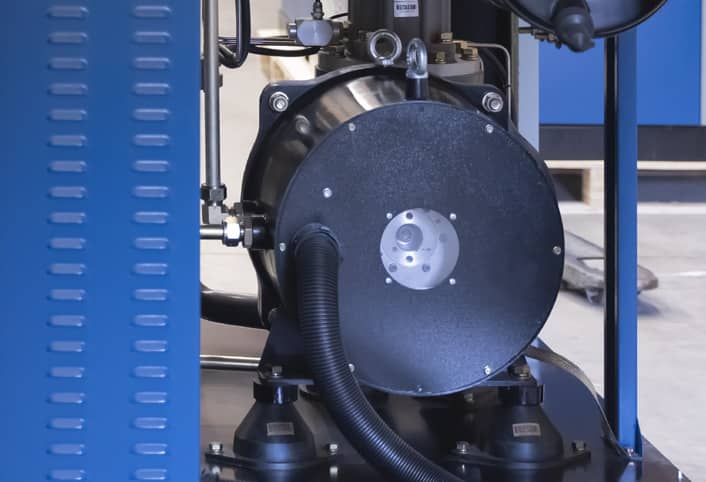

1-10 % - Bezeztrátový převod Přímé spojení mezi šroubovým blokem a motorem nemá žádné ztráty, které jsou přítomné u dalších typů převodů, zejména u klínových řemenů. |

3-15 % - Přesné nastavení tlaku Moderní řídící jednotky umožňují nastavit přesně takový tlak, který je zapotřebí s přesností na 0,01 bar. 1 bar tlaku navíc přitom odpovídá zhruba 7% energie. |

|

|

|

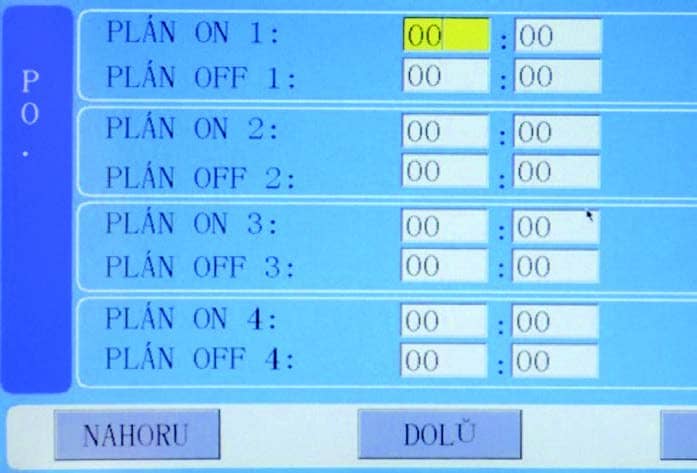

| 1-5 % - Eliminace spotřeby na úniky Software v jednotkách umožňuje nastavit týdenní plán s odstávkami, aby se zamezilo zbytečné výrobě vzduchu na pokrytí úniků, např. v noci nebo o víkendech. |

2-5 % - PM-motor s účinností IE4 Nejmodernější generace elektrických motorů s permanentními magnety snižuje náklady na spotřebu energie oproti standardům IE2/IE3 až o několik procent. |

1-2 % - Ventilace s regulací otáček Chod ventilátoru činí okolo 5% celkové energie a přitom často běží, i když to není zapotřebí. Přidaný frekvenční měnič reguluje chod ventilátoru přesně podle potřeby. |

Monitoring ICONS - Absolutní přehled nad kompresorem

Pokud využíváte ve své firmě stlačený vzduch, který nezbytně potřebujete pro zajištění provozu dílenských a výrobních technologií, je zcela nezbytné mít pod kontrolou jeho zdroj - kompresor. Moderní IoT řešení ICONS umožňuje do kompresoru snadno instalovat elektronická zařízení, která dokáží detekovat provozní parametry nebo komunikovat s řídícími jednotkami a data posílat pomocí integrované SIM-karty na server výrobce, odkud je můžete Vy nebo servisní středisko sledovat ve svém počítači nebo mobilním telefonu. Instalací systému ICONS získáte tolik potřebný přehled nad stavem MH a údržby, energetickou spotřebou stroje nebo můžete mít okamžitě k dispozici informace o havárii či provozních problémech.

![]()

Nejprodávanější

Řazení produktů

Výpis produktů

Olejem mazaný šroubový kompresor s extrémním objemovým výkonem a s kapalinou chlazeným PM-motorem IE4 byl vyvinut zejména s ohledem na co nejefektivnější výrobu stlačeného...

Inovativní a úsporný malý šroubový kompresor SCR-11/10PM2 pro úsporu až 50 % elektrické energie. Maximální výkon 1 500 l/min o tlaku 10 bar. Plynulá regulace otáček frekvenčním...

Inovativní a úsporný malý šroubový kompresor pro úsporu až 50 % elektrické energie. Maximální výkon 950 l/min o tlaku 10 bar. Plynulá regulace otáček frekvenčním měničem, přímý...

Vysoce úsporný šroubový kompresor s plynulou regulací otáček frekvenčním měničem. Kompresor je vybaven přímým bezeztrátovým pohonem 1:1 a vysoce efektivním elektromotorem IE4 s...

Revoluční malý šroubový kompresory s příkonem 4 kW v konceptu tradičních pístových kompresorů s tlakovou nádobou 200 l. Maximální tlak na výstupu je 10 bar při průtoku vzduchu...

Olejem mazaný šroubový kompresor s extrémním objemovým výkonem a s kapalinou chlazeným PM-motorem IE4 byl vyvinut zejména s ohledem na co nejefektivnější výrobu stlačeného...

Komfortní šroubový kompresor s příkonem 15 kW praktickém provedení s tlakovou nádobou a kondenzační sušičkou pro úsporu instalačního prostoru. Maximální tlak na výstupu je 10...

Inovativní a úsporný malý šroubový kompresor pro úsporu až 50 % elektrické energie. Maximální výkon 2 000 l/min o tlaku 10 bar. Plynulá regulace otáček frekvenčním měničem,...

Originální vysoce kvalitní minerální olej pro šroubové kompresory SCR v kanystru s objemem 5 l. Pro výměnu oleje u šroubových kompresorů značky SCR - Shanghai Screw Compressor...

Originální vysoce kvalitní minerální olej pro šroubové kompresory SCR v kanystru s objemem 20 l. Pro výměnu oleje u šroubových kompresorů značky SCR - Shanghai Screw Compressor...

Olejem mazaný šroubový kompresor s pevnými otáčkami a přímým spojením šroubového bloku s elektromotorem pomocí pružné spojky. Ovládání zajišťuje elektronická řídicí jednotka...

Olejem mazaný šroubový kompresor s extrémním objemovým výkonem a s kapalinou chlazeným PM-motorem IE4 byl vyvinut zejména s ohledem na co nejefektivnější výrobu stlačeného...

SCR-4/8XA je bezolejový spirálový kompresor s příkonem 3,7 kW pro trvalou dodávku ultračistého vzduchu dle třídy ISO 8573.1.0 při tlaku 10 bar o výkonu až 350 l/min. Díky...

SCR-2/8XA je bezolejový spirálový kompresor s příkonem 2,2 kW pro trvalou dodávku ultračistého vzduchu třídy 0 při tlaku 10 bar. Díky pokročilé spirálové technologii zajišťuje...

Olejem mazaný šroubový kompresor s extrémním objemovým výkonem a s kapalinou chlazeným PM-motorem IE4 byl vyvinut zejména s ohledem na co nejefektivnější výrobu stlačeného...

Olejem mazaný šroubový kompresor s extrémním objemovým výkonem a s kapalinou chlazeným PM-motorem IE4 byl vyvinut zejména s ohledem na co nejefektivnější výrobu stlačeného...

Olejem mazaný šroubový kompresor s extrémním objemovým výkonem a s kapalinou chlazeným PM-motorem IE4 byl vyvinut zejména s ohledem na co nejefektivnější výrobu stlačeného...

Revoluční malý šroubový kompresory s příkonem 2,2 kW v konceptu tradičních pístových kompresorů s tlakovou nádobou 90 l. Maximální tlak na výstupu je 10 bar při průtoku vzduchu...

Samostatný šroubový kompresor s příkonem 18,5 kW bez vzdušníku a sušičky vzduchu. Maximální tlak na výstupu je 10 bar při průtoku vzduchu 2 590 l/min. Elektronická jednotka...

Samostatný šroubový kompresor s příkonem 22 kW bez vzdušníku a sušičky vzduchu. Maximální tlak na výstupu je 10 bar při průtoku vzduchu 3 090 l/min. Elektronická jednotka...

Revoluční malý šroubový kompresory s příkonem 2,2 kW v konceptu tradičních pístových kompresorů s tlakovou nádobou 200 l. Maximální tlak na výstupu je 10 bar při průtoku vzduchu...

Revoluční malý šroubový kompresory s příkonem 3 kW v konceptu tradičních pístových kompresorů s tlakovou nádobou 200 l. Maximální tlak na výstupu je 10 bar při průtoku vzduchu...

Revoluční malý šroubový kompresory s příkonem 5,5 kW v konceptu tradičních pístových kompresorů s tlakovou nádobou 200 l. Maximální tlak na výstupu je 10 bar při průtoku vzduchu...

Samostatný šroubový kompresory s příkonem 11 kW bez tlakové nádoby. Maximální tlak na výstupu je 10 bar při průtoku vzduchu 1 416 l/min. Elektronická jednotka Infologic2 ve...

Komfortní šroubový kompresor s příkonem 11 kW praktickém provedení s tlakovou nádobou a kondenzační sušičkou pro úsporu instalačního prostoru. Maximální tlak na výstupu je 10...

Samostatný šroubový kompresory s příkonem 15 kW bez tlakové nádoby. Maximální tlak na výstupu je 10 bar při průtoku vzduchu 1 680 l/min. Elektronická jednotka Infologic2 ve...

Komfortní šroubový kompresor s příkonem 5,5 kW praktickém provedení s tlakovou nádobou a kondenzační sušičkou pro úsporu instalačního prostoru. Maximální tlak na výstupu je 10...

Komfortní šroubový kompresor s příkonem 7,5 kW praktickém provedení s tlakovou nádobou a kondenzační sušičkou pro úsporu instalačního prostoru. Maximální tlak na výstupu je 10...

Revoluční malý šroubový kompresory s frekvenčním měničem a příkonem 3,0 kW v konceptu tradičních pístových kompresorů s tlakovou nádobou 200 l. Maximální tlak na výstupu je 10...

Revoluční malý šroubový kompresory s frekvenčním měničem a příkonem 4,0 kW v konceptu tradičních pístových kompresorů s tlakovou nádobou 200 l. Maximální tlak na výstupu je 10...

Revoluční malý šroubový kompresory s frekvenčním měničem a příkonem 5,5 kW v konceptu tradičních pístových kompresorů s tlakovou nádobou 200 l. Maximální tlak na výstupu je 10...

Šroubový kompresor s přímým pohonem, výstupním tlakem 10 bar v praktickém provedení se vzdušníkem o objemu 200 litrů a kondenzační sušičkou pro úsporu instalačního prostoru....

Šroubový kompresor s přímým pohonem, výstupním tlakem 10 bar v praktickém provedení se vzdušníkem o objemu 200 litrů a kondenzační sušičkou pro úsporu instalačního prostoru....

SCR-22/7XA je bezolejový spirálový kompresor s příkonem 22,2 kW pro trvalou dodávku ultračistého vzduchu dle třídy ISO 8573.1.0 při tlaku 7 bar o výkonu až 1 400 l/min. Díky...

SCR-22/8XA je bezolejový spirálový kompresor s příkonem 22,2 kW pro trvalou dodávku ultračistého vzduchu dle třídy ISO 8573.1.0 při tlaku 8 bar o výkonu až 1 400 l/min. Díky...

SCR-22/10XA je bezolejový spirálový kompresor s příkonem 22,2 kW pro trvalou dodávku ultračistého vzduchu dle třídy ISO 8573.1.0 při tlaku 10 bar o výkonu až 1 400 l/min. Díky...

Vysoce úsporný šroubový kompresor s plynulou regulací otáček frekvenčním měničem. Kompresor je vybaven přímým bezeztrátovým pohonem 1:1 a vysoce efektivním elektromotorem IE4 s...

Vysoce úsporný šroubový kompresor s plynulou regulací otáček frekvenčním měničem. Kompresor je vybaven přímým bezeztrátovým pohonem 1:1 a vysoce efektivním elektromotorem IE4 s...

SCR-30/10XA je bezolejový spirálový kompresor s příkonem 29,6 kW pro trvalou dodávku ultračistého vzduchu dle třídy ISO 8573.1.0 při tlaku 10 bar o výkonu až 1 400 l/min. Díky...

SCR-30/7XA je bezolejový spirálový kompresor s příkonem 29,6 kW pro trvalou dodávku ultračistého vzduchu dle třídy ISO 8573.1.0 při tlaku 7 bar o výkonu až 1 400 l/min. Díky...